TESTIMONIALS

Matt Brown, The Port City Group:

“I don’t care what you are doing to improve die life or reduce tool maintenance. Whatever it is, take one more step and treat your inserts with Solvenite, the results will amaze you!"

Lee Kittle, Muskegon Die Casting:

“The heat check we historically filed around the 62mm bore at the bottom of the part is now non-existant at 70K! On past inserts I've seen this area require filing between 2500 to 5000 shots. This is a huge cost savings for the plant in regards to re-work, weld repairs, part quality, and uptime.”

Dan Norton, Anderton Casting (formerly CH Die Casting):

“Using Solvenite on VascoMax 300 Steel. We are casting Silafont 36 Structural Alloy. The part is planetary carrier. Before, untreated we trashed the die after 15k shots. Now we are getting 80k – 100k shots. We have 7 dies with 3 more on order . . . They will have Solvenite for sure!”

Vern Moss, Minnesota Die Caster:

“Quick update on the sample MaXXshot core. The core now has 32350 shot with little solder on it. They will do a light polish on the core for the first time. They have said it is doing very well, much better than any other coatings they have tested.”

Prolong Surface Technologies has over 100 repeat customers . . .and growing.

PERFORMANCE DATA

MAIN CAVITY TESTS

BEFORE: Shown Untreated 70k (A380 Alloy)

AFTER: Shown Solvenite Treated 70k (A380 Alloy)

TWO CAVITY DIE AT 65K SHOT

CAVITY #1: Untreated

CAVITY #2: Solvenite Treated

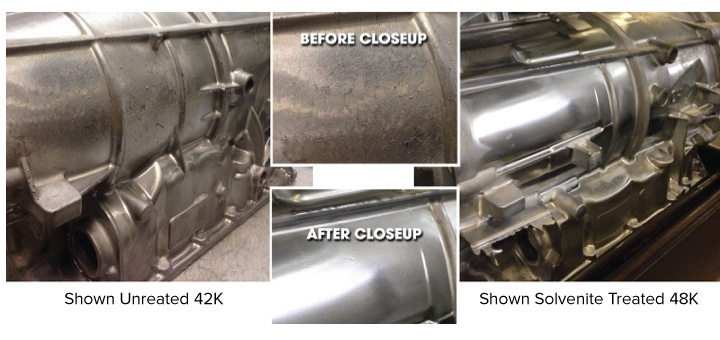

Low Fe Structural Alloys (Silafont, Mercalloy, Aural, etc.)

PROVEN RESULTS: Increase your Die Life when using Structural Alloys

BEFORE: Shown Untreated 35k (Low Fe Alloy)

AFTER: Shown Solvenite Treated 35k (Low Fe Alloy)

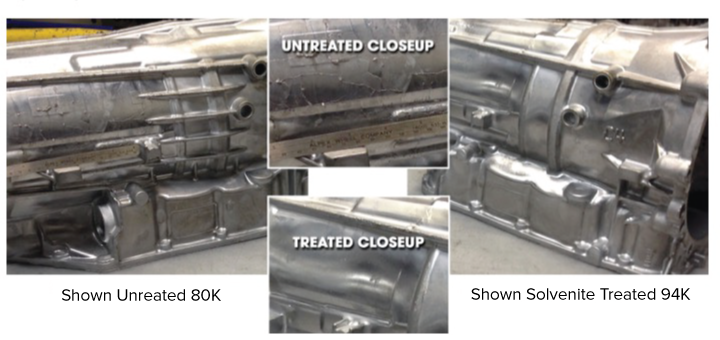

Solvenite Rejuvenates Mid-Life Tooling

SIMILAR CASTINGS WITH IDENTICAL GATING

THE SOLVENITE DIFFERENCE

UNTREATED:

Shown at 100k

TREATED:

Shown at 100k

UNTREATED:

Shown at 10k

TREATED:

Shown at 30k

SEND US YOUR FEEDBACK OR INQUIRIES

Please fill out the form below with any questions or comments on your experience with Solvenite or Maxxshot! We will get back to you as soon as possible.